For general lighting purpose in shops, offices, houses, schools etc. Single phase a.c. supply is commonly used. Hence instead of d.c. motors, the motors which work on single phase a.c. supply are very popularly in use. These a.c. motors are called single phase induction motors. The numerous domestic applications use single phase motors. The power rating of such motors is very small. Some of them are even fractional horse power motors, which are used in applications like small toys, small fans, hair dryers etc. This chapter explains the construction, working principle and applications of various types of single phase induction motors.

Similar to a d.c. motor, single phase induction motor has basically two main parts.one rotating and other stationary. The stationary part in single phase induction motors is called stator while the rotating part is called rotor.

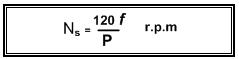

The stator has laminated construction, made up of stampings. The stampings are slotted on its periphery to carry the winding called stator winding or main winding. This is excited by a single phase a.c. supply. The laminated construction keeps iron losses to minimum. The stampings are made up of material like silicon steel which minimises the hysteresis loss. The stator winding is wound for certain definite number of poles means when excited by single phase a.c. supply, stator produces the magnetic field which creates the effect of certain definite number of poles. The number of poles for which stator winding is wound, decides the synchronous speed of the motor. The synchronous speed is denoted as Ns and it has a fixed relation with supply frequency f and number of poles P. The relation is given by,

The induction motor never rotates with the synchronous speed but rotates at a speed which is slightly less than the synchronous speed.

The rotor construction is of squirrel cage type. In this type, rotor consists of uninsulated copper or aluminium bars, placed in the slots. The bars are permanently shorted at both the ends with the help of conducting rings called end rings. The entire structure looks like cage hence called squirrel cage rotor. The construction and symbol is shown in the Fig..1

|

| Fig. 1 |

As the bars are permanently shorted to each other, the resistance of the entire rotor is very very small. The air gap between stator and rotor is kept uniform and as small as possible. The main feature of this rotor is that it automatically adjusts itself for same number of poles as that of the stator winding.

The schematic representation of two pole single phase induction motor is shown in the Fig.2.

No comments:

Post a Comment